CKAS-FLYW990 Liquid Turbine Flowmeter (explosion-proof mark:Ex d IIC T6 Gb)

CKAS-FLYW990 series liquid turbine flowmeter is a precision flow measuring instrument composed of turbine flow sensor and display instrument. It is a velocity flowmeter manufactured with foreign advanced technology and is one of the ideal flowmeters for liquid flow measurement.

Liquid turbine flowmeter is widely used in petroleum, chemical industry, metallurgy, water supply, papermaking, environmental protection, food, medicine and other fields. It is suitable for liquid flow measurement without impurities, strong corrosiveness and low viscosity. It can be used together with intelligent flow totalizer or quantitative controller to realize over-range alarm or automatic quantitative control and other functions.

Product Features

1.High accuracy, generally up to Grade 1.5, 1 and 0.5 (supplied by agreement);

2.Good repeatability, with short-term repeatability up to 0.05%~0.2%. Due to its good repeatability, the flowmeter can be highly accurate by regular calibration or online calibration, which is preferred in trade settlement;

3.Three-point correction of instrument coefficient, intelligent compensation of instrument coefficient non-linearity, and site correction;

4.All valid data will be kept for 10 years after power failure;

5.Range ratio, up to 1:15 for medium and large diameter and 1:10 for small diameter;

6.Compact and light structure, convenient installation and maintenance, and large flow capacity;

7.Lower limit of low flow measurement;

8.Wide flow measurement range;

9.Low power consumption and high stability;

10.Power supply: 24VDC, ≤18W;

11.Output power: < 0.5W.

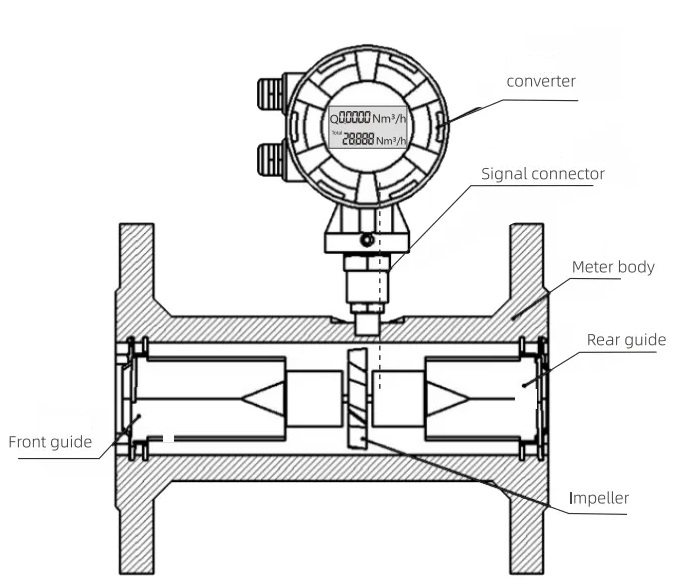

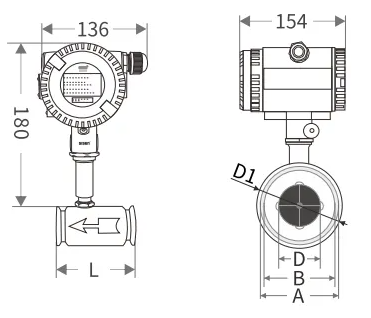

Structure diagram of CKAS-FLYW990 liquid turbine flowmeter

Working Principle

When the measured fluid flows through the sensor, since the blade of the impeller has a certain angle with the flow direction, the impulse of the fluid makes the blade have a rotating torque, and the blade rotates after overcoming the friction torque and fluid resistance. After the torque is balanced, the speed is stable. Under certain conditions, the speed is proportional to the flow velocity. Due to the magnetic conductivity of the blade, it is in the magnetic field of the signal detector (consisting of permanent magnetic steel and coils). The rotating blade cuts the magnetic line of force, periodically changing the magnetic flux of the coil, so that electrical pulse signals are induced at both ends of the coil. This signal is amplified and shaped by the amplifier to form a continuous rectangular pulse wave with a certain amplitude, which can be transmitted to the display instrument remotely to display the instantaneous flow or cumulative flow of the fluid.

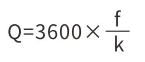

Within a certain flow range, the pulse frequency f is proportional to the instantaneous flow Q of the fluid flowing through the sensor, and the flow equation is:

The instrument coefficient of each sensor is filled in the verification certificate by the manufacturer, and the k value is set in the supporting display instrument to display the instantaneous flow and cumulative total amount.

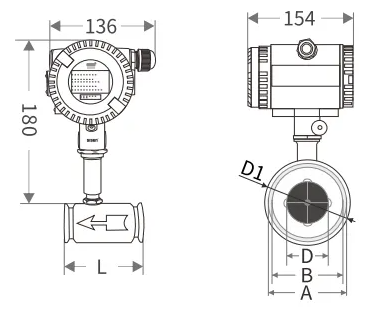

DN4-DN300 flanged turbine flowmeter dimensions

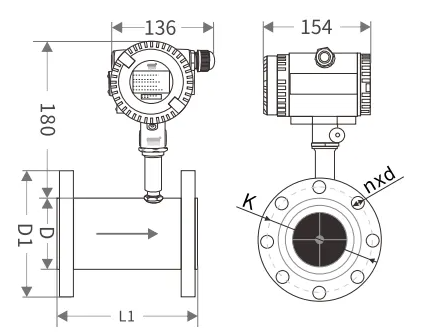

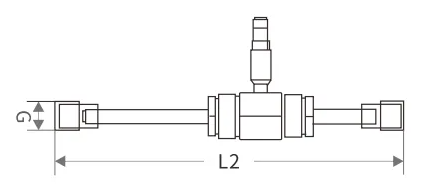

DN4-DN100 clamp connection type turbine flowmeter size diagram

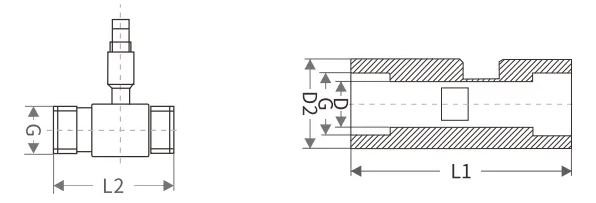

DN4 ~ DN10 threaded connection turbine flowmeter surface (including straight section part) size diagram

DN15-DN100 threaded connection turbine flowmeter (without straight pipe section) dimensions

DN15 ~ DN100 clamping connection type turbine flowmeter size diagram